office security has usually been a top priority in industrial environments. nevertheless, it is frequently the trustworthiness of equipment and right techniques that Participate in a pivotal role in ensuring the usefulness of security protocols. One such important ingredient in industrial functions is lifting slings, which not simply facilitate substantial-stakes lifting functions and also impact office basic safety. This blog site dives into how superior-good quality lifting slings and rigging materials assist enterprises greatly enhance security though bettering operational effectiveness.

Table of contents:

The purpose of trusted gear in protecting against Workplace mishaps

frequent Inspection and routine maintenance Practices for Lifting Slings

education staff on right Usage of Rigging Supplies

Understanding Load restrictions and basic safety things in Lifting Operations

The job of Reliable Equipment in protecting against Workplace incidents

trusted products is the foundation of any Harmless office, and lifting and rigging provides are not any exception. Lifting slings, which include artificial lifting slings and limitless spherical slings, are precisely engineered to take care of important hundreds efficiently. substantial-high quality artificial lifting slings, like those from trustworthy makers for example Gostern Rigging, make sure toughness and dependability, reducing the likelihood of apparatus failure. Poor-high-quality machines, On the flip side, may lead to hazardous incidents, like load drops and structural damages. right resources, for example superior-toughness polyester or nylon, and adherence to international protection benchmarks (for instance ISO 4878, EN1492-2, and JB/T8521.2) make sure that lifting slings fulfill essential performance conditions. regardless of whether Utilized in building, shipbuilding, or logistics, reputable lifting slings strengthen not only basic safety and also provide operators with satisfaction, enabling them to concentrate on efficiency without having stressing about probable tools failure.

standard Inspection and Maintenance methods for Lifting Slings

Even the highest-high-quality lifting slings require normal inspection and routine maintenance to maintain their integrity and functionality. plan checks for signs of put on and tear, like fraying, tears, and abrasions, are crucial. artificial lifting slings, while resilient, can degrade after some time as a result of variables for example UV exposure, Excessive temperatures, or publicity to corrosive substances. Industries should here set up stringent routine maintenance schedules and supply workers with tips to make sure lifting slings are inspected right before just about every use. For example, employing protective round sling addresses can avoid abrasions when functioning in rigorous environments, thus extending the lifespan on the slings. purchasing a process to track the service lifestyle of kit ensures that slings which have attained their services Restrict are replaced instantly, reducing opportunity safety dangers.

Training workers on Proper utilization of Rigging provides

Despite outstanding-quality lifting devices, security is often compromised In case the workforce is not trained to employ it accurately. This really is very true for lifting slings, wherever incorrect use may lead to accidents In spite of reliable gear. Providing teaching on the correct way to connect a lifting sling, protected masses, and estimate load boundaries makes sure that staff can maximize the protection and overall performance of lifting and rigging provides.Exclusive emphasis must be placed on proper dealing with techniques, including applying applications like slip-proof components or versatile synthetic round slings, which are meant to distribute load bodyweight evenly. A effectively-educated team not just lessens pitfalls but additionally optimizes efficiency, as workforce come to be self-confident in managing even elaborate lifting tasks.

comprehending Load restrictions and basic safety aspects in Lifting Operations

comprehension the load restrictions and safety components of lifting equipment is a vital phase to ensuring safe functions. Every lifting sling usually comes with a defined Operating load Restrict (WLL), which specifies the maximum load that may be securely lifted. by way of example, Gostern lifting slings are available in a wide range of WLLs, from 0.5T to 1000T, making certain suitability for several lifting scenarios, from lightweight machines to major industrial machinery. It’s important that staff are experienced to discover and calculate the necessary security factor and by no means exceed the lifting sling's ability. Tools like synthetic unlimited slings, which comply with demanding basic safety expectations and have customizable lengths, offer Increased versatility and security for numerous industrial programs, together with building, Electrical power, and delivery functions. suitable load balancing also maximizes protection. artificial spherical slings, As an example, excel in distributing load fat evenly to lower strain on both of those the sling plus the load by itself, mitigating the chance of stress concentrations and structural failures.

applying robust safety protocols with superior-quality devices including synthetic lifting slings makes a safer, a lot more productive operational ecosystem. From selecting reliable tools to fostering a perfectly-qualified workforce and adhering to load capacities, each and every action helps mitigate hazards. By integrating these techniques into your office, You improve not simply safety but will also extended-phrase operational trustworthiness. to be certain your lifting operations operate effortlessly, take into consideration Gostern’s extensive selection of artificial fiber slings, endless round slings, and various lifting and rigging materials. With customizable choices and rigorous protection standards, their items are tailor-made to satisfy the demanding needs of currently’s industries.

Amanda Bynes Then & Now!

Amanda Bynes Then & Now! Daniel Stern Then & Now!

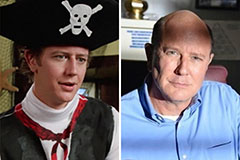

Daniel Stern Then & Now! Judge Reinhold Then & Now!

Judge Reinhold Then & Now! Hailie Jade Scott Mathers Then & Now!

Hailie Jade Scott Mathers Then & Now! Nicki Minaj Then & Now!

Nicki Minaj Then & Now!